Why Recycle Your Vehicle?

It’s Time To Get Your Older, Higher Polluting Vehicle Off the Road

Retire Your Ride has its roots in the original National Vehicle Scrappage Program introduced by the federal government to provide incentives for people to trade in their older, higher-polluting vehicles, resulting in cleaner air and a healthier environment.

There are currently 18 million light vehicles registered for use on Canadian roads. The average lifespan of a vehicle in the 1960s was just less than 162,000 km. Today this is approaching 225,000 km.¹ This means that Canadians can and often do keep their old vehicles on the road for years longer than they used to.

Recycling your older vehicle can make a huge impact. By participating in Retire Your Ride, you will reduce your impact on the environment, make extra money, and support local green businesses.

Older vehicles are typically less fuel-efficient than new vehicles of a similar size and lack the latest vehicle technology for cutting air pollution and reducing smog-forming emissions. As a result, the fuel consumption and smog-forming emissions are usually greater for older vehicles than newer vehicles. These older vehicles also contain hazardous fluids and materials like mercury switches that need to be treated responsibly at the end of their life.

With the introduction of new technologies, newer vehicles can be much more fuel efficient than their older counterparts. By keeping fuel consumption in mind, you could save 20-40% per year in fuel consumption costs by recycling in your old car for a new model in the same category.

Retire Your Ride is the only national program that exclusively utilizes vehicle recyclers that adhere to the Canadian Automotive Recycler’s Environmental Code. By rewarding these environmental leaders within the Automotive Recycling Industry, Retire Your Ride is stimulating business in the green economy.

Air Quality

Tail pipe emissions and smog

Smog is a big problem in Canada and one which affects the health of all Canadians. In fact, in a recent report, the Ontario Medical Association (OMA) estimated that smog- related premature mortality accounts for approximately 9,500 deaths annually in Ontario. Across Canada, cars, trucks and buses are major sources of smog pollution, especially in densely populated urban areas. Smog-forming pollutants include nitrogen oxides, volatile organic compounds and fine particulate matter. Vehicles from 2003 and older can be up to 39x more polluting than a newer vehicle!

Improvements in the design of vehicle exhaust systems have reduced pollution from individual vehicles significantly over the past 25 years. Environment Canada projects that smog causing emissions, specifically HCs and NOx, from the total auto sector are currently in decline as newer, cleaner vehicles replace older, higher emitting vehicles in the fleet.

The auto industry has introduced five successive generations of environmental equipment on new vehicles. Today’s motor vehicles reduce smog-causing emissions by as much as 99% from uncontrolled levels.

By removing over 120,000 vehicles from Canadian roads, Car Heaven has reduced smog-forming pollution by 4,925 tonnes.

Responsible Automotive Recycling

When you’re done with your vehicle, be aware of who you’re selling it to… It’s An Important Decision.

Where you take your vehicle when it reaches the end of the road can make the difference between an environmental disaster and responsible earth stewardship. The truth is, not everybody handles end-of-life and accidented vehicles the way we do.

It’s almost unbelievable, but there are some scrap operations who buy cars just to crush them and sell them for the value of the metal, allowing toxic fluids and heavy metals to escape into the soil and groundwater. They don’t recycle any usable parts and pay no regard to the damage they’re doing to the environment.

Retire Your Ride recyclers are the guaranteed way to ensure your end-of-life vehicle (ELVs) is processed properly. Each vehicle goes through a methodical process to maximize reclamation and minimize environmental impact. They have invested in the training and equipment to ensure each and every vehicle is handled in an environmentally responsible manner. They have been all been audited by an independent third party to ensure that their practices, facilities and training meet the requirements of the Canadian Automotive Recyclers’ Environmental Code.

Here’s What We Do With Your Vehicle

Here’s What We Do With Your Vehicle

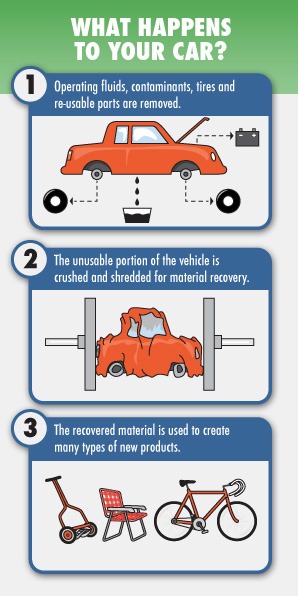

Your car is the largest and most recyclable product you own. No sorting required – the recyclers that work with Retire Your Ride will reuse and recycle 80% of your vehicle and will make sure the remaining materials are disposed of responsibly.

Once your vehicle has been picked up by one of Retire Your Ride’s participating auto recyclers, it will be recycled at their facility in three stages:

- Pre-treatment: drainage of operating fluids

- Parts Re-use: dismantling of parts and components

- Recycling of Materials

What happens to your car?

The Recycling Process

¹Automotive Industries Association of Canada, 2005